Rebuilding the BMW N18 Engine for Strong and Reliable Performance

Posted by Mamta Sharma on 9th Jan 2026

Rebuilding a BMW N18 engine might seem complicated, especially if the engine has high mileage or has been under heavy use. Over time, important parts like pistons, bearings, and timing components can wear out, causing lower performance, engine noises, and rough running. Trying to fix just one part may not solve these issues.Using a SneedSpeed N18 engine rebuild kit gives you all the necessary parts in one package. It ensures compatibility, reduces mistakes, and makes the process much smoother. Each part is designed to work perfectly with the others, so the rebuilt engine performs reliably and efficiently.

A full rebuild with SneedSpeed improves engine power, oil control, and overall smoothness. The engine will feel almost like new and will last for many more miles. Following a complete rebuild process ensures you get long-term reliability and avoids repeated repairs.Rebuilding the engine with a quality kit also saves time and money. With everything organized and ready, the process is methodical and easy to follow, even for those with moderate mechanical experience.

Engine Removal and Full Tear Down Preparation

Removing the engine and preparing it carefully is the foundation for a successful rebuild. If this step is done right, it saves time and prevents mistakes during assembly. A thorough preparation allows for proper inspection and cleaning of every engine component.Removing the engine gives full access to all sides, making it easier to clean and inspect. All external parts such as intake, exhaust, and accessories are taken off carefully. Bolts and small hardware are organized in labeled trays to prevent loss and confusion later.Photographs and notes during disassembly help with correct reassembly. Stripping the engine down to the bare block allows detailed inspection and cleaning, setting up a strong foundation for the SneedSpeed N18 rebuild kit components.

- Removing the engine safely: The engine is carefully lifted out to avoid damage to the car or components. Full access makes the work easier and prevents mistakes.

- Taking off all external parts: Intake, exhaust, sensors, and brackets are removed slowly. This keeps connections safe and prevents breakage.

- Organizing hardware and small parts: Bolts, nuts, and small components are stored in labeled trays or bags. This makes reassembly faster and easier.

- Documenting with photos and notes: Photos and notes record the location of each component. They serve as a guide during assembly.

- Stripping the engine to the bare block: Removing all internal parts allows for deep cleaning and detailed inspection. The block is ready for new parts.

Detailed Check of Critical Engine Components Before Rebuild

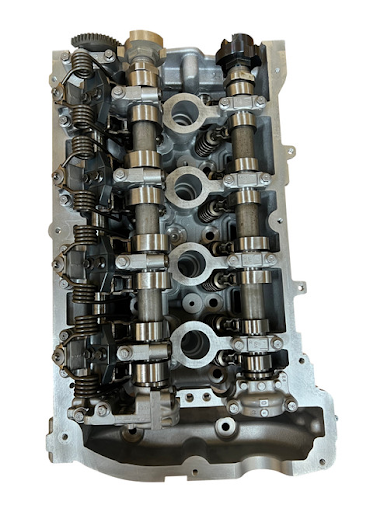

Inspection is a critical step in any rebuild. Every internal part must be checked for wear, damage, or imperfections. Identifying problems early ensures that only healthy components are reused, and all worn parts are replaced.Cylinder walls, crankshaft journals, and camshaft lobes are carefully examined for scratches, scoring, or uneven wear. Bearings and seals are checked for heat marks, stiffness, or cracks. Old or damaged parts can cause engine knocking, low oil pressure, or reduced performance.Recording all measurements and issues helps you select the correct components from the SneedSpeed N18 rebuild kit. A thorough inspection reduces the risk of future failures and ensures a smooth, reliable rebuild.

- Checking cylinder walls for wear: Cylinder walls are examined for scratches, scoring, or uneven wear. This ensures proper compression and reduces oil burning.

- Inspecting crankshaft journals: Crankshaft surfaces must be smooth to maintain correct oil pressure. Damaged journals can lead to knocking.

- Reviewing camshaft condition: Worn cam lobes reduce engine efficiency and timing. Early detection prevents performance problems.

- Examining bearings and seals: Bearings and seals are inspected for cracks, heat marks, and stiffness. New parts prevent oil leaks and engine damage.

- Recording all measurements: Accurate measurements help select the correct SneedSpeed components, ensuring a perfect fit during assembly.

Engine Block Cleaning and Preparation Work

A clean and well-prepared block ensures the new parts function properly. Dirt, sludge, or old gasket material can affect lubrication, sealing, and overall engine performance. Proper preparation reduces the risk of early failures and ensures smooth operation.Cylinder walls may be honed to help new piston rings seat correctly. Oil passages are cleaned thoroughly to remove debris and ensure proper lubrication. Bearing clearances are measured carefully to allow smooth movement. Bolt threads are cleaned to help tighten parts evenly.Preparing the block properly sets a solid foundation for a reliable engine rebuild using SneedSpeed components. A clean and ready block improves engine life and performance.

- Honing cylinder walls for proper sealing: Honing ensures piston rings seal correctly, restoring compression and reducing oil consumption.

- Cleaning oil passages thoroughly:Dirt and sludge are removed from oil galleries to protect bearings and moving parts.

- Checking bearing clearances: Proper clearances ensure smooth oil flow and prevent overheating or premature wear.

- Cleaning bolt holes and threads: Clean threads allow proper torque application and prevent leaks or damage.

- Final cleaning before assembly:The block is wiped and inspected for debris to ensure all new parts fit perfectly.

Engine Assembly Using the SneedSpeed N18 Rebuild Kit

Installing all components from the SneedSpeed N18 rebuild kit is the main step in the rebuild. Careful installation ensures reliable operation, smooth performance, and long-term durability.Bearings are coated with assembly lube for protection during first startup. Pistons and rings are fitted carefully to restore compression and smooth movement. Crankshaft rotation is checked, and timing chains, guides, and tensioners are installed to ensure correct engine timing. Seals and gaskets are replaced to prevent leaks.Following torque instructions and sequence charts is essential. Each part is installed in the correct order to maximize engine life and performance. Using SneedSpeed ensures that every part fits correctly and functions as intended.

- Installing main and rod bearings

The main and rod bearings are placed carefully in their correct positions. Each bearing is coated with an assembly lube to protect it during the first engine start. This lubrication helps reduce friction before oil pressure builds up. Proper bearing installation is key to avoiding early engine damage. - Fitting pistons and ring sets

Pistons and rings are installed slowly and with care into each cylinder. The rings are aligned correctly to help seal the combustion chamber. This step restores compression and helps the engine run smoothly. Correct piston fitting also improves power and reduces oil burning. - Checking crankshaft rotation

Once the crankshaft is installed, it is turned by hand several times. This check makes sure everything moves freely without tight spots. Smooth rotation confirms that bearings and clearances are correct. Catching issues now prevents serious problems later. - Installing timing chain and guides

The timing chain, guides, and tensioner are installed to keep engine timing accurate. These parts control when valves open and close. Proper timing prevents misfires and engine noise. New components also reduce the risk of chain stretch or failure. - Replacing all seals and gaskets

All old seals and gaskets are removed and replaced with new ones. Fresh seals stop oil and coolant leaks. Good sealing helps maintain engine pressure and temperature. This step ensures clean operation and long-term reliability.

Final Assembly and Safe Engine Break-In

The final stage ensures the rebuilt engine is ready for normal driving. Proper reassembly and break-in protect all new parts and help them settle correctly.External components like intake, exhaust, and accessories are reinstalled carefully. Fresh oil and coolant are added. The engine is started slowly while monitoring oil pressure, temperature, and unusual noises. Following a proper break-in procedure allows the parts from the SneedSpeed N18 rebuild kit to seat correctly and ensures long-term performance.

- Reinstalling external components:Intake, exhaust, and accessories are installed carefully and checked twice for proper fit.

- Adding fresh oil and coolant:New fluids protect internal parts and help the engine reach normal operating temperatures.

- Starting the engine for the first time:The engine is started gently to monitor performance and ensure proper lubrication.

- Checking for leaks and abnormal sounds:Minor issues are corrected immediately to prevent serious engine damage.

- Following proper break-in procedures:Gentle driving allows new pistons, rings, and bearings from the SneedSpeed N18 rebuild kit to seat properly.

Conclusion

Rebuilding a BMW N18 engine may seem complicated, but following a clear process makes it straightforward. A full rebuild addresses worn internal components that simple repairs cannot fix, ensuring smoother operation, improved performance, and long-term reliability.Using a SneedSpeed N18 engine rebuild kit gives confidence that all parts fit correctly and function together. It reduces mistakes, saves time, and increases engine longevity. This kit is ideal for BMW enthusiasts, owners, and professional mechanics looking for a reliable, all-in-one solution.Contact SneedSpeed today to get your N18 rebuild kit and bring your BMW engine back to life safely and efficiently!